The mills of Assynt

Comunn Eachdraidh Asainte - Assynt Historical Society

There are a number of mill sites in Assynt. These are of the horizontal stone type. The illustration below shows the cross-section of a horizontal mill with the main components.

Components

Hopper where the bulk of the grain would be placed. It would probably be fixed to the roof of the mill.Shaker This feeds the grain into the hole in the centre of the top millstone.

Millstones Only the top stone revolves. The lower one is fixed to the mill floor.

Wedges control the gap between the millstones

Mill floor is normally made of wood.

Vertical and cross Beams connect the wedges to the Tirl.

Tirl complete with paddles and main shaft which at the top is fixed to the bottom of the upper millstone.

Fluim directs the water from the mill race onto the paddles of the tirl causing it to rotate, turning the top millstone. As the grain is fed by the shaker into the hole in the top millstone. It is ground between the fixed bottom stone and the rotating top stone, eventually feeding out to the outside of the stones.

In simple mills, the flour would fall onto the wooden mill floor, where it would be swept up and collected. More advanced mills would have some form of collecting tray. Driving in the wedges raises the vertical and cross beams thereby lifting the top stone. Doing this, increases the gap between the two stones to control the fineness of the grind.

Principles of horizontal Mills

In this type of mill only the top stone revolves. The lower one is stationary and fixed to the mill floor. The drawing below shows how the corn was fed into the shaker from the hopper. From the shaker it was fed into the centre of the grinding stones. A weight attached to the shaker rests on the top stone. As the top stone revolves, the weight, dragging across the top millstone, vibrates the shaker, providing a controlled feed of corn.

If the two wedges are driven underneath the small cross bar, it lifts the beam on which the tirl sits. As the tirl is fixed to the top stone, it lifts that stone making the gap between the stones larger. This is how the miller controls the fineness of the grind. The corn is fed into the centre of the top stone and finds its way into the gap between the two. As it is ground, it finds its way to the outside of the stones dropping onto a cloth spread on the mill floor. Although, more advanced mills would have had some form of container built in to catch the flour.

If the two stones are in contact, the friction would probably have stopped the top stone from turning. The miller would have widened the gap to allow the top stone to start turning until it picked up speed an then adjusted the gap to suit his grinding.

Altan Na Bradhan

Both footpaths are in good order and members of the public are welcome to visit this site.

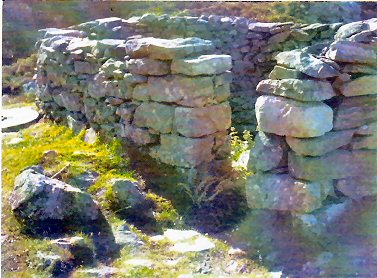

Various millstones lying at the site at Alt na Bradhan